Ballast & Subgrade Monitoring

Monitor washout prone & unstable areas

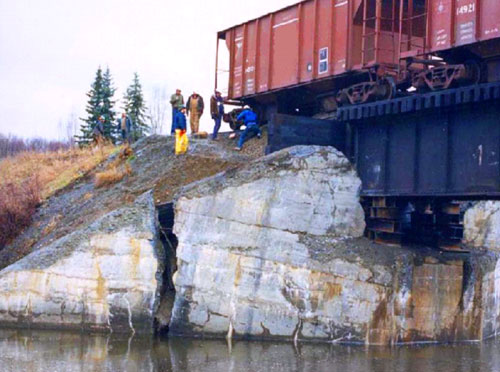

Sensors protecting track near a drainage basin.

Ballast Integrity Sensors provide continuous, real-time monitoring of subgrade movement in reference to the track structure. Infrastructure issues such as washouts, abutment scour and general earth shift can be monitored 24 hours a day in all weather conditions to provide for a safer and more robust railroad. The Ballast Integrity Sensor provides a simple, cost effective, quickly deployable & reliable solution for monitoring movement in all directions.

Homeland security threats; Loss of life; Litigation; Equipment loss; Roadbed damage; cargo destruction and loss; Hazardous waste cleanup; and Evacuation of civilian populations are costly endeavors that can be better managed by continuously monitoring the condition of the ballast and subgrade.

Monitor washout prone & unstable areas

- Washouts created by flooding or plugged culverts

- Sinkholes and side-scour from water damage

- Track buckling due to sun kinks and weak track

- Impact Damage to bridge structures over highways and waterways

- Lateral Movement of track caused by heavier axle loads.

This system can be installed as stand-alone hardware or easily retrofitted to all existing signal systems. The hardened ground mounted sensor is extremely reliable and tamper-proof with flexible, site-specific installation patterns.

* Qualifies for US Government grants (up to 80%) by the 2008 Rail Safety Improvement Act as stated in Section 101-105.