Vehicle Hunting Systems

Truck or Bogie hunting is characterized by rapid sustained side-to-side motion of the trucks/bogies. This condition is especially problematic for empty or lightly loaded vehicles and for vehicles with worn wheels. In addition to damaging the car, truck hunting imposes excessive lateral forces on the track structure thereby accelerating track degradation and increasing the propensity for flange climb derailments. We offer two different truck hunting detection technologies based on customer preference.

Hunting Detector ( Strain Gage Sensors as utilized by the WILD systems )

Hunting detector in conjunction with WILD sensors

Strain gage based hunting detection technology is based on measuring & analyzing the vertical & lateral wheel forces in a truck for a pattern of oscillation that is characteristic of truck hunting. Strain gauge circuits are mounted to the rails whereby a data collection system then analyzes the force pattern and calculates a severity index if hunting is detected. Alarm reports are then generated and sent to the railroad as required.

This force-based Truck Hunting Detector requires that the strain gauge circuits be permanently applied to the rails & periodically re-calibrated. This system can be set up as a stand-alone system but may also be more economically integrated into a Weigh-in Motion or WILD system.

- Strain Gage based system measures AOA, wheelset lateral force, and wheelset vertical force at several locations

- Computes wheelset measurements and associates each axle with its appropriate car

- Determines several wheelset tracking errors including hunting

- Permanent strain gage sensor application

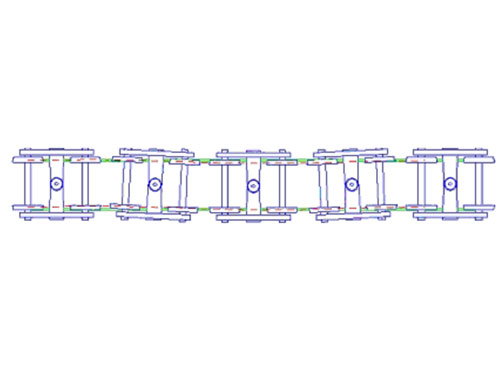

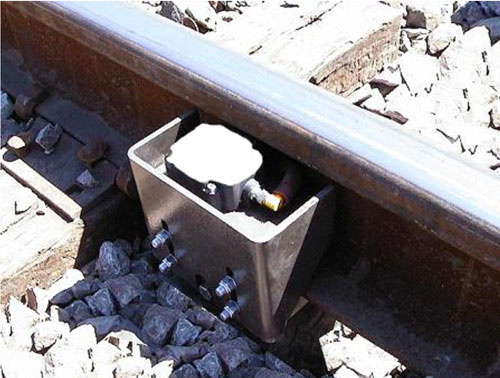

Wheelset Tracking - Optical Guidance Detector (OGD)

Non contacting proximity sensor to detect wheelset offset, hunting and warp

Proximity sensor technology is a Truck Hunting & Tracking Error Detector which utilizes a series of non-contacting proximity sensors placed on the rails to measure the trajectory of a wheelset. This system analyzes an axle's lateral displacement data to determine if it exhibits an oscillating pattern consistent with truck hunting. If such a pattern is detected, a proprietary severity index is calculated for the axle and compared to an alerting threshold. An alarm report is then automatically generated & transmitted as required.

Another feature of the Truck Hunting & Tracking Error Detector is its ability to detect trucks that track poorly in one direcction. Some trucks have suspension or wheel wear defects that cause them to skew and run with wheels forced into flange contact with the rail. Trucks with these "tracking errors" experience greatly increased rates of wheel flange wear as well as suspension component degradation. Finally, wheels that run in constant flange contact with the rail are much more likely to pick a switch or climb the rail. This Hunting & Tracking Error Detector requires no re-calibration & is easy to install/ remove.

- Optical based system measures AOA, wheelset lateral position, and rail lateral position at several locations

- Computes wheelset measurements and associates each axle with its appropriate car

- Determines several wheelset tracking errors including hunting

- Bolt on sensor application