Vehicle Steering & Lateral Force (TPD - Truck Performance Detector)

Small Detector Housing with Solar Power Option

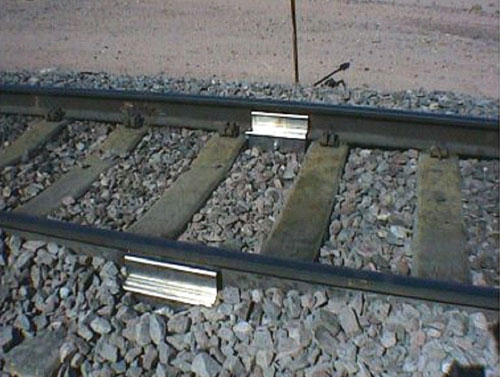

TPD Rail Sensors

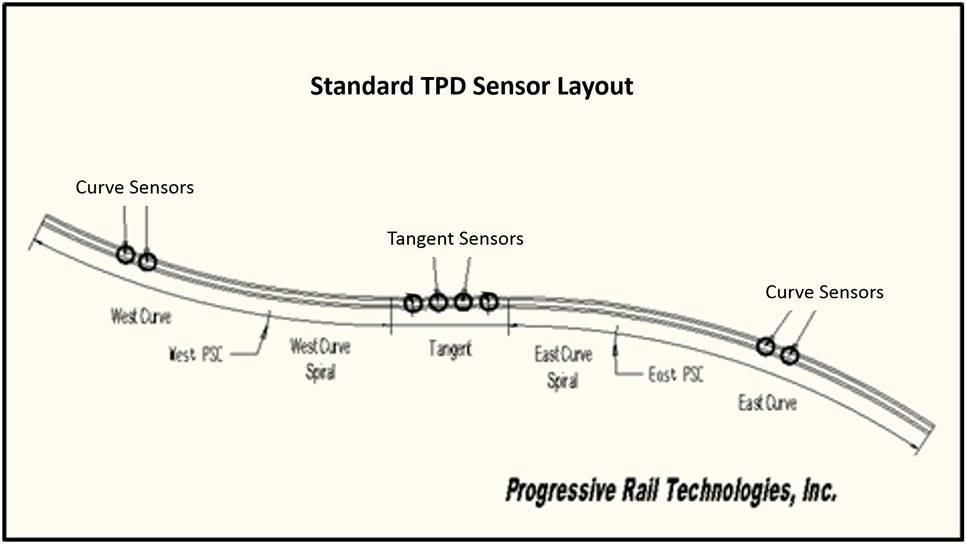

Vehicle Steering Monitoring devices are often referred to as Truck Performance Detectors (TPD's). These systems consist of a series of rail mounted sensors which measure the vertical & lateral wheel forces as well as the axle angle-of-attack (AOA). The TPD track section has a specific geometry such that the performance of the railcars can be evaluated in tangent track and in left and right-hand curves of 4 to 6 degrees (North American) or 430 to 300 Meter Radius. Rail mounted sensors are monitored by an automatic data collection system that includes an Automatic Equipment Identification (AEI) reader for associating the wheel forces with the proper vehicles.

The TPD data collection system records individual wheel forces, axle AOA's, and car identification information for each passing train. The system then automatically analyzes the wheel force data immediately after the train pass in reference to the following conditions:

Typical TPD Layout

- Gauge Spreading

- Flange Climb

- Truck Warp (Skew)

- Improper Steering

- Improper Truck Rotation

- Vertical Twist

- Unbalanced Wheel Loads

- Overloaded Car

Alerts are sent immediately for any vehicle that exceeds the threshold of any of the above performance criteria. The force data and performance indices are then transmitted to various databases as required. Find defects such as:

- Worn Friction Wedges

- Missing Column Wear Plates

- Broken Suspension Springs

- Hollow Worn Wheels

- Twisted Car Bodies

- Dry/Binding Center Bowls

- Tight Side Bearings

- Mismatched Side Frames

We also offer comprehensive system health monitoring, alert broadcasting and database services.